Innovation

Here you will find innovative processing and application techniques developed by HOFMANN NATURSTEIN in partnership with architects and engineers. Our novel engineering solutions for building with natural stone open up new design and construction possibilities for architecture.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

Cubist Facade elements made of massive natural stone

For the Frankfurt project ML Forty Seven, our engineering department developed a facade with cubistic natural stone elements in special design. Formed in the form of a highly thermally insulated curtain wall, this type of facade design with natural stone represents a real innovation.

- 1

- 2

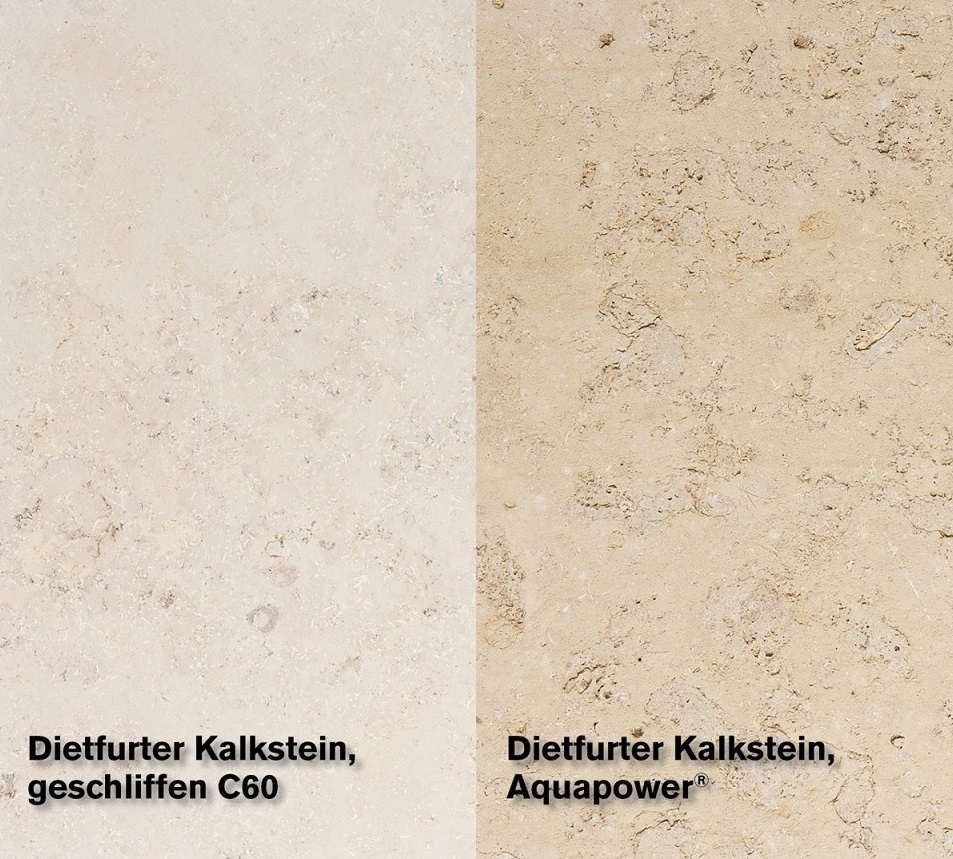

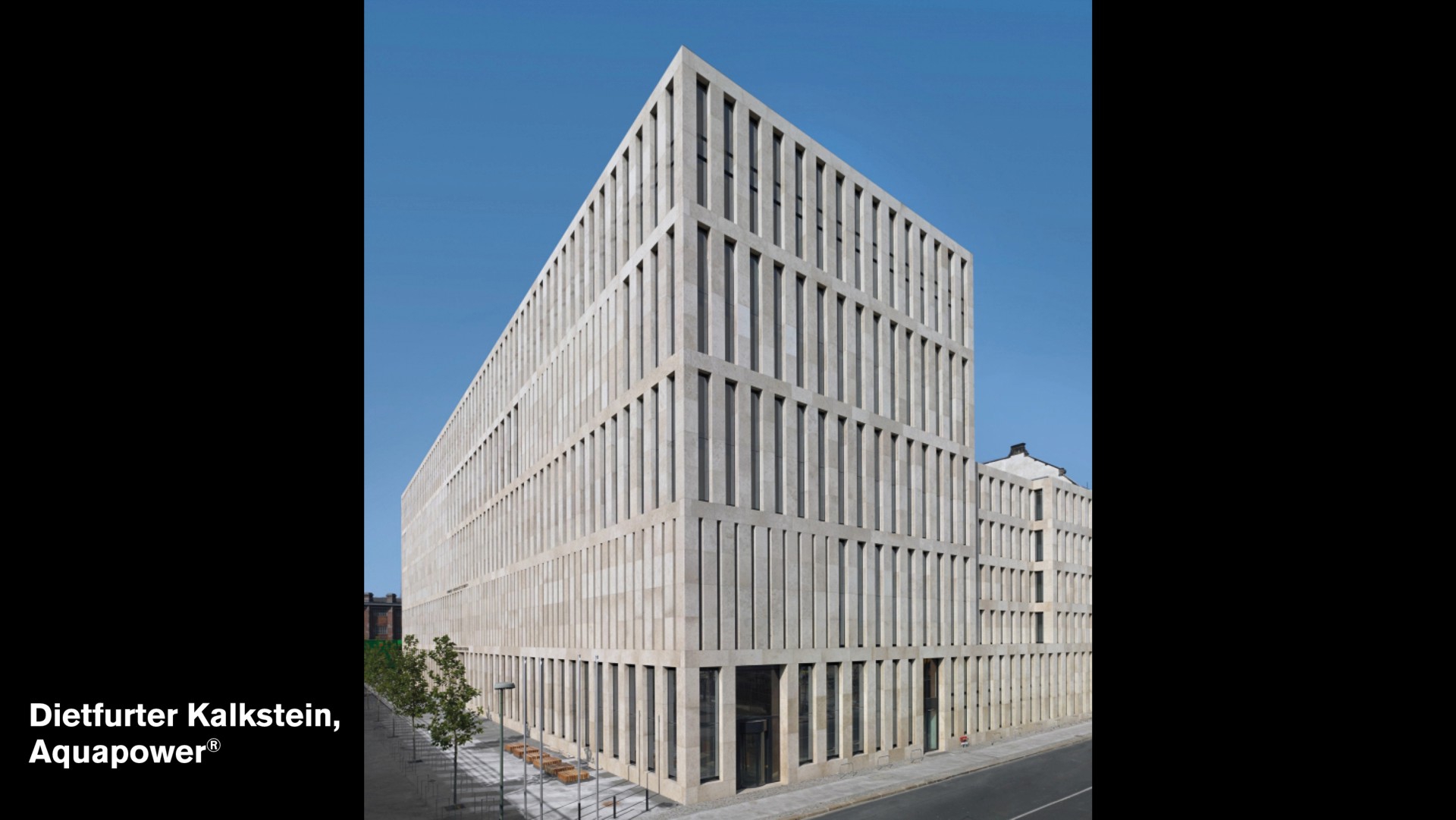

Surface treatment AQUAPOWER

“AQUAPOWER” is a new type of surface treatment. The stone is processed with high water pressure up to 2,000 bar, this contributes to a special optical solidity in the case of limestones and granites (more on facades in granite); the rough surface appears more color-intensive.

All natural stones with Aquapower surface treatment here at a glance.

- 1

- 2

- 3

- 4

- 5

- 6

Natural stone roof

Sebald Kontore, Nürnberg

The roof covering in natural stone with massive hooked stones set sophisticated accents in the heterogeneous urban environment.

E.ON AG, Düsseldorf

The stone roof of E.ON Düsseldorf, covering more than 1,000 square meters as a modern sealed and thermally insulated concrete roof with natural stones, was realized with our special knowledge.

- 1

- 2

Surface treatment HANDSPLIT

The handsplit surface gives facades a noble and unique appearance. The surface treatment of the facade slabs in the manufactory by our stonemasons makes each stone haptically unique. Depending on the incidence of light and the viewing angle, the result is a different impression.

Spatial design with natural stone

Machine-controlled three-dimensional stone processing with millimeter precision gives architecture unlimited possibilities in the implementation of your design ideas or in the replication of existing forms using high-precision 3D scanning.

Blast resistant stone facades

HOFMANN NATURSTEIN offers various solutions for structural protection of high-rise buildings. Slim elements allow the combination of explosion protection and natural stone with a variety of design options. This allows the protective measure to be inconspicuously integrated into the overall architectural appearance. Reinforced natural stone elements with a component thickness of 5 cm or more protect load-bearing components such as lobby columns, exterior beams and entire facades from progressive collapse as well as the blast wave and debris throw. Our in-house engineering team will be happy to advise you on the development of an explosion-proof facade. HOFMANN NATURSTEIN is also a partner of a leading company for explosion-proof glass. In combination, a closed outer skin (more on facade natural stone) can be created that meets the highest safety requirements.

- 1

- 2

Noiseless renovation

The target of a complete façade replacement without interrupting office operations – i.e. without noise pollution – was solved by our specialist knowledge for the Behördenzentrum in Frankfurt and the Philip-Johnson-Haus in Berlin.

- 1

- 2

- 3

- 4

Pre-stressed natural stone – stone bridge across the Hessenring

The combination of the material properties of granite and steel was realized with the realization of a prestressed natural stone bridge pier for a pedestrian bridge in Bad Homburg. The 5-fold higher compressive strength of granite compared to the best concrete grade, combined with the high tensile strength of high-strength steels as a prestressed element, allow slender component constructions of unprecedented dimensions.

- 1

- 2

- 3

Jointless construction – Sonnentor (“Gate of the sun”)

We test and measure the stone architecture of today against the examples of building history. The knowledge of the jointless building art of the Incas was banned by the Spanish conquerors as a pagan art. Nevertheless, seamless 20-ton blocks in Cusco/Peru still bear witness to this technique today. By using newly developed precision-controlled diamond contour wire saws and 5-axis milling machines, production comes very close to jointless stone precision.

The sun gate shown in the adjacent photo was built by us using jointless stone construction technique.

It is made of Koesseine Royal Blue Granite from the Fichtelgebirge.

It is located at our company headquarters in Gamburg and is open to the public at all times.